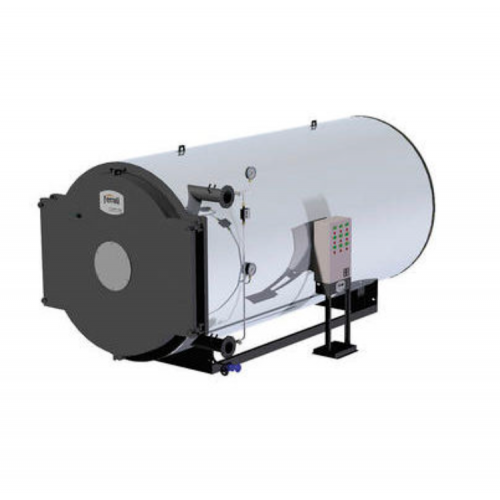

-Diathermic oil boilers featuring a helical tube bundle with one or more turns and three effective flue passes.

-Designed to operate in combination with jet burnerson liquid (including high density) or gas fuel.

-Standard design pressure 10 bars.

-Operating temperature up to 300°C for mineral oilsand 350°C for synthetic oils, with a temperaturedifference between oil inlet and outlet of around 40°C.

-Upon request boilers can be developed with differenttemperature values and differences from thoseindicated above.

-Construction with two concentric rings inside in acylindrical sheet metal body that’s tight to the flue gas. The first “ring” represents the furnace that the flame extends along; the second “ring” is the start of a three flue pass circuit that optimises use of the entire heat exchange surface, making it advantageous to use low NOx burners.

-Tube bundle made from carbon steel without welding.

-Access to the furnace is available through a burnerdoor hinged to the boiler that can be opened from the right or the left; the door is lined on the inside with a suitably thick layer of refractory concrete and features a flame inspection opening and burner anchor plate.

-The rear smokebox is bolted to the boiler, and linedon the inside with insulating concrete, and is fitted withcleanout door and attachment for the flue connection.

-The boiler body is lined by a suitable layer of high density rock wool, protected by stainless steel plate (AISI 430); this reduces heat loss and improves overall efficiency.